5E-AF3000 Ash Fusion Analyzer

The 5E-AF3000 Ash Fusion Analyzer automatically monitors cone deformation temperatures in coal ash, biomass ash, and mold powders. By doing so, it ensures proper boiler function and helps prevent issues like slagging (buildup of melted ash) and fouling (clogging). This is crucial for confirming that coal is suitable for high-temperature applications, enhancing the efficiency and reliability of industrial processes, particularly in power generation and other industries where coal combustion plays a key role.

Product Category: Analytical Instruments, Coal, Metal Ore Mining, Cement & Non-metallic resources, Ash fusion determinator, CKIC.

Features

- Automatically determines four critical temperatures: DT, ST, HT, and FT.

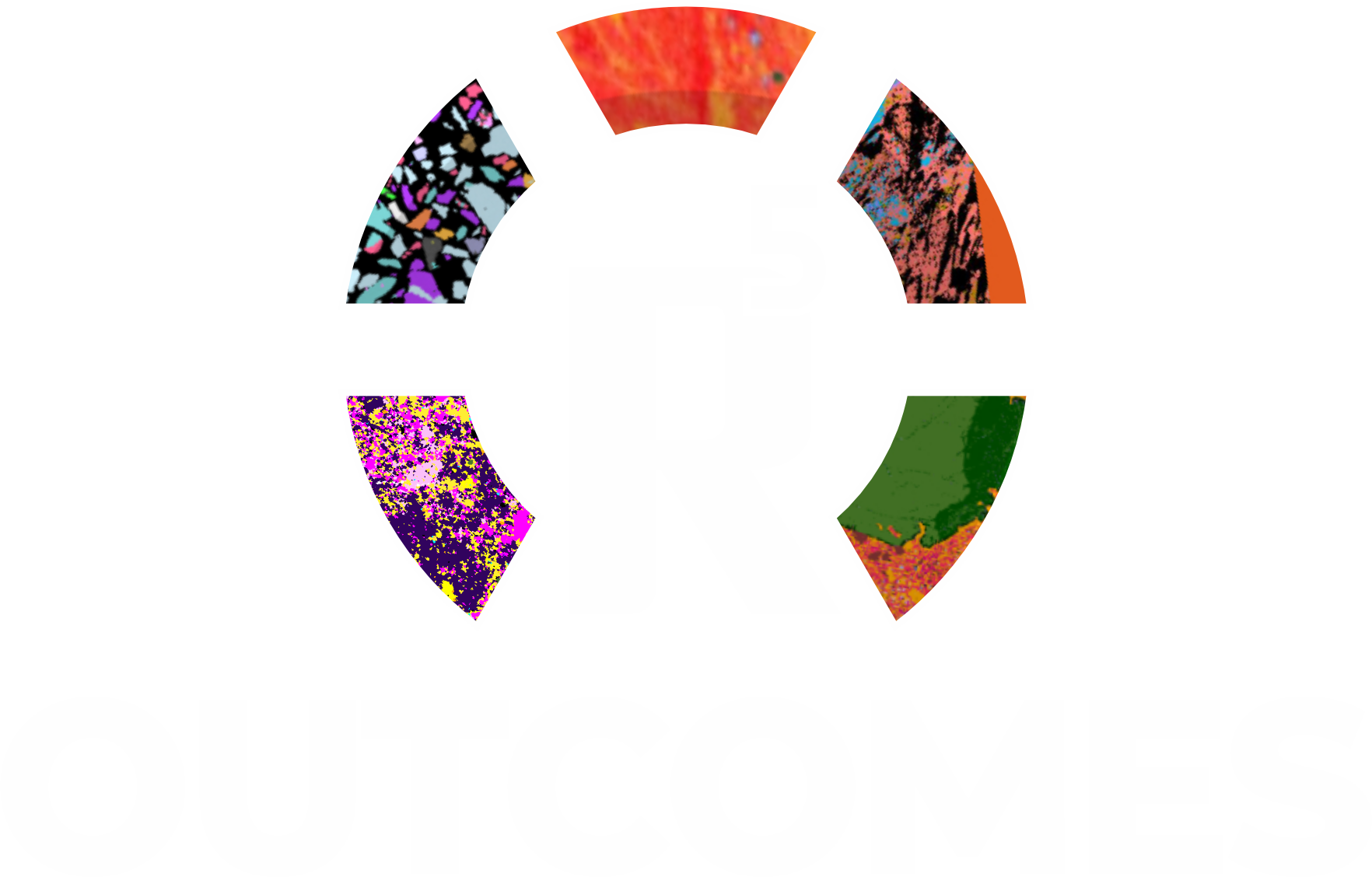

- Equipped with a 3.2 Mega-pixel professional camera, providing high-resolution imaging for precise analysis.

- Features a durable Si-Mo heating element and an ergonomic vertical furnace design, ensuring consistent and stable operating temperatures.

- Video recording capability for playback, enabling both automatic and manual identification.

- Simulates atmospheric conditions using graphite and activated carbon, effectively reducing operational costs by eliminating gas consumption.

- Integrated automatic gas leakage detection system with an auditory alarm, and gas flow is terminated upon detection.

Application

5E-AF3000 Ash Fusion Analyzer is used to determine ash cone deformation temperatures in coal ash, coke ash, biomass ash and mold powders automatically, which are critical to the boiler functioning properly and to avoid slagging and fouling.

The 5E-AF42 Series Ash Fusion Analyzer and the 5E-AF3000 Ash Fusion Analyzer are both advanced tools designed to monitor ash cone deformation temperatures. However, the 5E-AF3000 differs in the following key aspects:

Sample Capacity: The 5E-AF3000 can test up to 5 samples for GB and ASTM standards, and up to 7 samples for ISO standards.

Camera: The 5E-AF3000 is equipped with a 3.2 Mega-pixel professional camera, providing high-resolution imaging for more precise analysis compared to the 5E-AF42 Series.

Automation: The 5E-AF3000 features a durable Si-Mo heating element and an ergonomic vertical furnace design, ensuring consistent and stable operating temperatures. It also includes video recording capability for playback, enabling both automatic and manual identification, which is not available in the 5E-AF42

Series. Safety: The 5E-AF3000 integrates an automatic gas leakage detection system with an auditory alarm, automatically terminating the gas flow if leakage is detected, offering a higher level of safety compared to the 5E-AF42 Series.

Atmosphere Simulation: The 5E-AF3000 simulates atmospheric conditions using graphite and activated carbon, effectively reducing operational costs by eliminating the need for gas consumption, whereas the 5E-AF42 Series does not offer this feature.

In general, the 5E-AF42 Series is designed for flexibility and easy upgrades, with a focus on high automation and a user-friendly interface, while the 5E-AF3000 offers a higher camera resolution and additional capabilities for more detailed analysis.

Standard Configurations

| Computer Main analyzer A/C adapter Ash cone plate Activated carbon Graphite Standard Reference Material(GBW) | Dextrine Magnesia Combustion cup Duab kit Ash cone module Gasket kit Tool kit |

Optional Standard Configurations: 7 samples ash cone plate (ISO)

For more information or inquiries, please contact us.

Datasheet

| Model | 5E-AF3000 Ash Fusibility Determinator |

| Conforms to Method | AS 1038-1995, ASTM D1857/D1857M/E935/935M, ISO 540, GB/T 219, GB/T 30726, BS 1060-1995 |

| Max. Sample loading | GB and ASTM: 5 Samples ISO: 7 Samples |

| Max. Temp. | Up to 1600℃ |

| Temp. Control Precision | ±1℃ |

| Camera pixel | 3.2 Mega-pixel |

| Image Frame | 1 frame per 2℃ |

| Heating Rate | 4℃/min-20℃/min adjustable |

| Analysis Atmosphere | Oxidizing Atmosphere / Reducing Atmosphere |

| Power Supply | Single phase, AC220V±10%, 50/60Hz, ≤3.5kW |

| Net Weight | 65kg |

| Dimension(mm) | 480mm×470mm×740mm |