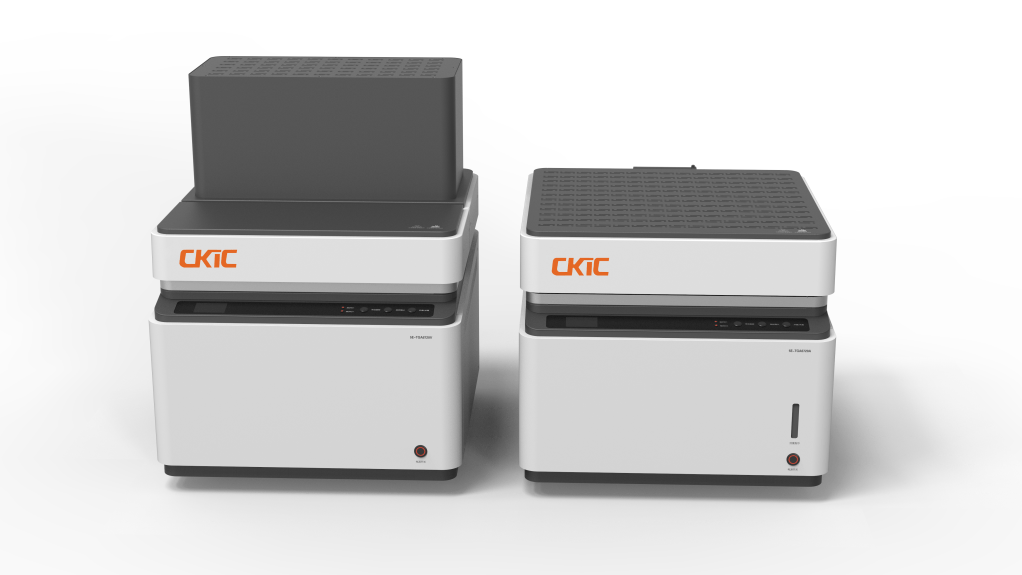

5E-TGA 67 Series Automatic Proximate Analyzer

The 5E-TGA67 Series Proximate Analyzer is a state-of-the-art instrument designed to determine moisture, ash, and volatile matter in various samples such as coal, coke, biomass, and iron ore. This analyzer offers unparalleled automation and efficiency, ensuring precise and reliable results.

Product Category: Analytical Instruments, Agriculture & Environment, Coal, Metal Ore Mining, Cement & Non-metallic resources, TGA, CKIC.

Features

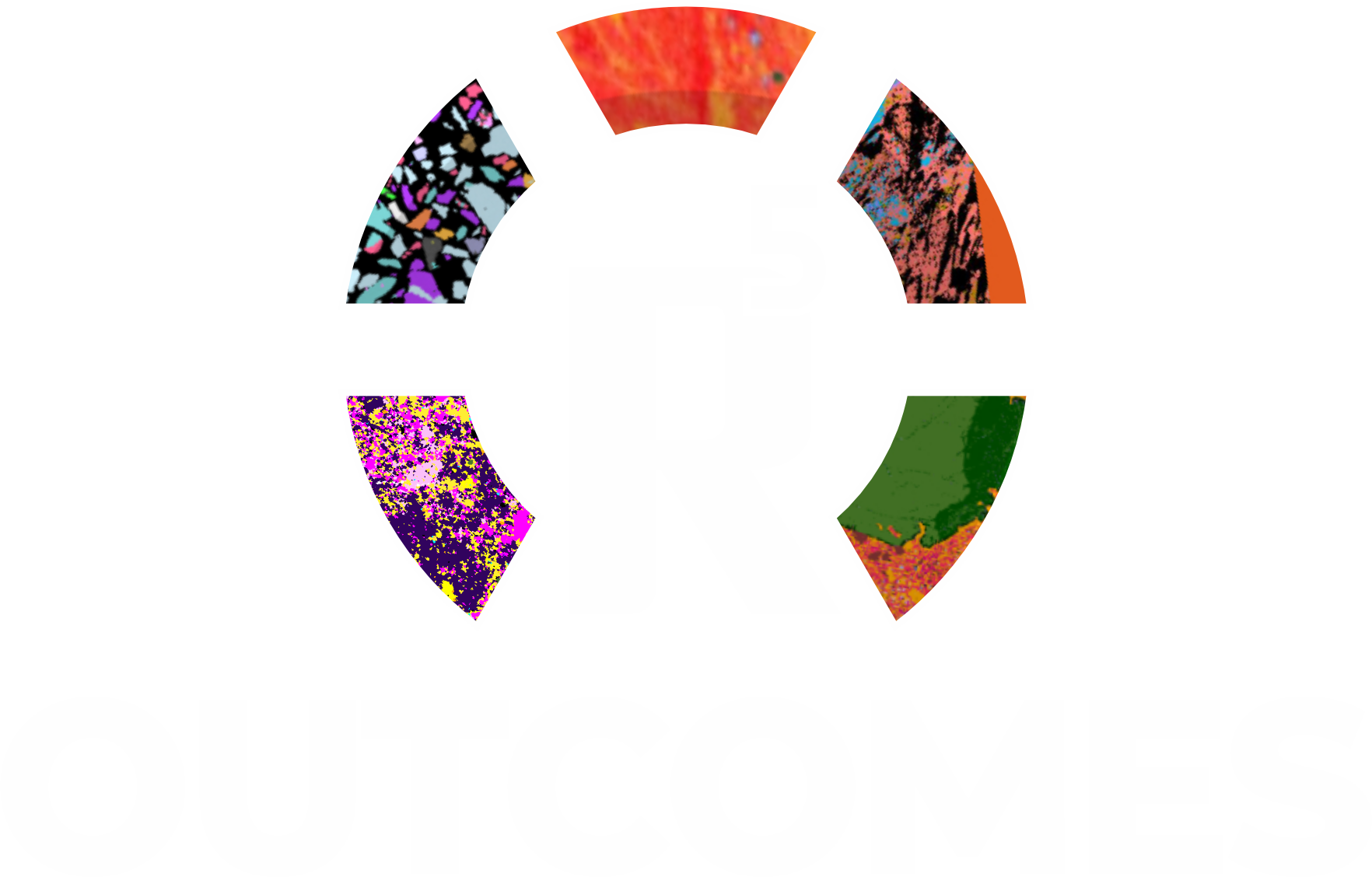

Proximate analysis (TGA) includes analysis of moisture content, ash content, volatile matter and the calculation of fixed carbon. Accurate results from proximate and ultimate analysis of coal, coke and biofuel are an important step in mining and processing operations.

Automation and Efficiency

- For accurate moisture and ash determination, samples should be evenly spread with a density not exceeding 0.1 g/cm².

- Operates without the need for an external gas source. The furnace cover opens automatically after analysis and is rapidly cooled by a powerful airflow, ensuring quick transitions between test cycles.

- Capable of analysing 24 samples per batch for moisture, ash, and volatile matter, with up to two batches completed within an 8-hour period.

Enhanced Safety

- Features a dual thermocouple system for superior heating protection, ensuring a stable and uniform temperature field. Additionally, magnetic induction positioning enhances operational precision.

- Incorporates multiple safety and recovery functions, including:

- Crucible and sample re-weighing

- Automatic recovery after power interruptions

- Out-of-tolerance warnings

- Self-diagnostic fault detection

Centralized Management

- Provides full traceability of test data and processes, including automated QC chart generation from QC sample data, ensuring compliance with CNAS standards.

- Real-time monitoring of furnace temperature, sample weight, sample ID, and position on a 4.3-inch colour display.

- Enables centralized control and maintenance of up to five proximate analyzers from a single computer and software interface.

Eco-Friendly Operation

- Integrated exhaust treatment system reduces dust, odour, and SO₂ emissions by over 90%, ensuring a safer and cleaner laboratory environment

Application

Models Available

- 5E-TGA6720A: Determines moisture and ash.

- 5E-TGA6720V: Determines volatile matter.

- 5E-TGA6721A: Determines moisture and ash without an exhaust gas treatment system.

- 5E-TGA6721V: Determines volatile matter without an exhaust gas treatment system.

The 5E-TGA67 Series Proximate Analyzer offers custom test methods tailored to specific sample types and industry requirements. This flexibility allows users to achieve accurate and reliable results for a wide range of applications.

- Coal & Coke Industry: The 5E-TGA67 Series Proximate Analyzer is extensively used in the coal industry to determine the moisture, ash, and volatile matter content of coal samples. This information is crucial for assessing the quality and energy content of coal, ensuring efficient combustion and reducing emissions. Additionally, this data is vital for optimizing the coking process and producing high-quality coke for metallurgical applications.

- Biomass Industry: The analyzer is also used in the biomass industry to analyze various biomass samples, such as wood chips, agricultural residues, and energy crops. Determining the moisture, ash, and volatile matter content of biomass is essential for improving the efficiency of biomass conversion processes and ensuring consistent fuel quality.

- Iron Ore Industry: The 5E-TGA67 Series Proximate Analyzer is employed in the iron ore industry to determine the proximate composition of iron ore samples. This information is important for optimizing the beneficiation process and producing high-quality iron ore concentrates.

Enhance your laboratory capabilities with the 5E-TGA67 Series Proximate Analyzers today!

For more information or inquiries, please contact us.

Datasheet

| Specification | Details |

| Model | 5E-TGA 67 Series |

| Analysis Content | Moisture, ash, and volatile matter |

| Conforms to Methods | GB/T30732, GB/T2001, GB/T28731, ISO17246, ASTM D7582, ISO18123/18122/18134, ISO11722, ISO1171 |

| Max. Sample Loading | 24 samples + 1 empty crucible |

| Analysis Time | Rapid method: about 150 mins; Classical method: about 250 mins (depending on the sample) |

| Sample Mass | 0.5-1.5g |

| Balance Precision | 0.1mg |

| Max. Temperature | 1050℃ |

| Temp. Control Precision | ±1℃ |

| Gas Supplied | Air/Nitrogen/Oxygen (in TGA 67A) |

| Exhaust Gas Treatment | Reduces dust, odor, and SO₂ emissions by over 90% (exclusive to TGA6720) |

| Operating Conditions | Ambient temperature: 0℃~40℃; RH: <85%; No strong vibration, strong electromagnetic interference, and corrosive gas |

| Communication Network | Ethernet |

| Power Supply | 220±22 V, 50-60 Hz; 5kW (for moisture-ash device) and 4kW (for volatile matter device) |

| Dimensions | TGA 67A: 655×795×570 (mm); TGA 67V: 655×720×840 (mm) |