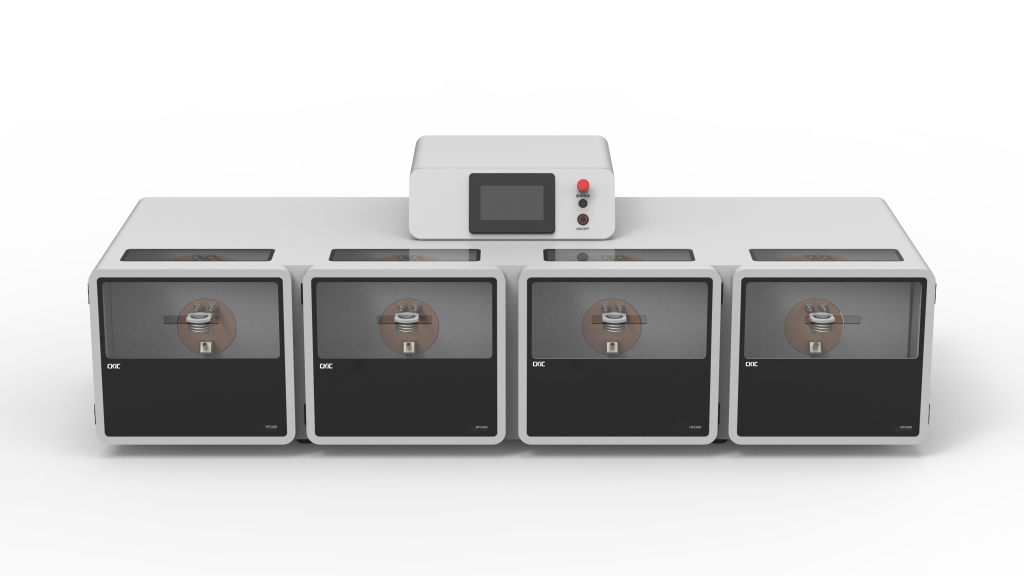

HF Series High-Frequency Induction Fusion Machine

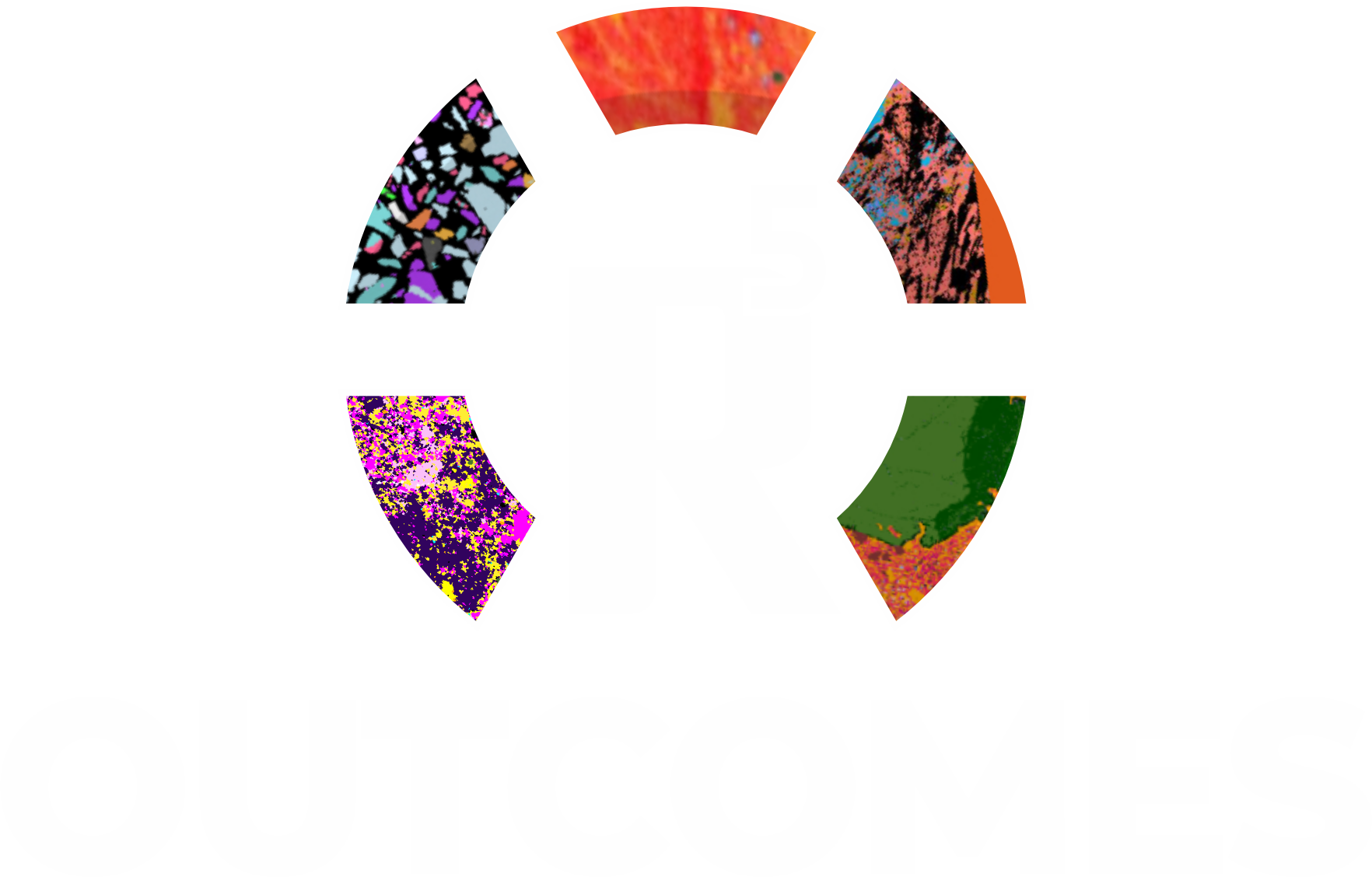

The HF Series High-Frequency Induction Fusion Machines are revolutionizing sample preparation, setting new benchmarks for laboratory excellence. These are designed to make glass beads for XRF analysis in different industries and applications, such as such as geology, building industry, metallurgy, cement industry, coal industry and more.

Product Category: Specific Sample Preparation for Analytical instruments, Agriculture & Environment, Coal, Metal Ore Mining, Cement & Non-metallic resources, Fusion machine.

Features

The Glass fusion method is an important technique for XRF sample preparation, which effectively reduces and eliminates undesirable factors such as particle effect, matrix effect, and mineral effect of samples. It greatly improves accuracy of XRF analysis.

Induction fusion machine adopts a high frequency induction heating design to achieve rapid warming and cooling with a reasonable structure; it also features a high precision infrared temperature measurement sensor and advanced PID temperature control for real-time temperature measurement and accuracy during the fusion process, which ensures excellent quality of the glass frit. HF3000 is easy to operate with a convenient touch screen interface.

High Automation

- Automatic sample melting and casting: users only need to put the sample into HF3000 and press one button to complete the entire process of pre-oxidation, heating and melting, shaking well, casting into shape, and cooling down.

- Automatic Shaking and mixing during the melting process to maintain the uniformity of the molten sample.

High Efficiency

- Induction heating design allows for rapid heating up and cooling down.

- Fast sample preparation speed of around 5-10mins/sample.

- High-precision infrared temperature measurement system, combined with PID intelligent temperature control, allows for accurate temperature control during the melting process

Easy Operation

- Touch screen design make HF Series easy to operate, safe and reliable. Operator can also self-set and save sample preparation programs for future use.

- According to different work load, single station, double station and four station modes are available for users to choose.

High Safety

- A heat–resistant ceramic protection device designed for the platinum crucible and forming mold to prolong their service life.

- The built-in exhaust system removes the harmful gas generated during the melting process to protect the operator’s health.

- The alarm of over-voltage, over-current, over-heating, over-temperature and lack of water to ensure safe and stable use.

Application

Models Available

- HF3000 | HF3200 | HF3400

- 1 workstation with 1 sample position (up to 1 sample per batch)

- 2 workstations with 1 sample position each (up to 2 samples per batch)

- 4 workstations with 1 sample position each (up to 4 samples per batch)

- HF3002 | HF3202 | HF3402

- 1 workstation with 2 sample positions (up to 2 samples per batch)

- 2 workstations with 2 sample positions each (up to 4 samples per batch)

- 4 workstations with 2 sample positions each (up to 8 samples per batch)

The HF Series High-Frequency Induction Fusion Machine is widely used for sample preparation in industries such as geology, metallurgy, cement industry, coal industry and building materials.

Upgrade your laboratory capabilities with the HF Series High-Frequency Induction Fusion Machine.

For more information or inquiries, please contact us.

Datasheet

| Models | HF30 Series | HF32 Series | HF34 Series |

| Number of Work Station | 1 | 2 | 4 |

| Sample(s) per Work Station | HF3000/3200/3400:1 HF3002/3202/3402:2 | ||

| Heating Method | High frequency induction heating | ||

| Temp. Control Method | High-precision infrared temperature sensor with PID temperature control technology | ||

| Molding Method | Automatic casting, 5-10 mins per batch | ||

| Control Method | Touch screen,automatically or manually | ||

| Cooling Method | Coil cooling with external water-cooling machine | ||

| Working Process | Preheating→Oxidation→Fusing→Shaking→Automatic casting→Cooling | ||

| Safety Protection | Over pressure,overflowing,overheating,lack of water,and over temperature protection | ||

| Requirements for Crucible | Platinum crucible (Pt/Au:95/5),85g each | ||

| Power Supply | Single phase, AC220 ±10% , 50/60Hz, protective grounding | ||

| One 32A circuit,8kW | Two 32A circuits or one 63A circuit,16kW | Four 32A circuits or one 63A circuit,32kW | |

| Net Weight | 45kg | 90kg | 180kg |

| Dimensions(L×W×H) | 480mm×840mm×580mm | 1000mm×840mm×640mm | 2000mm×840mm×640mm |