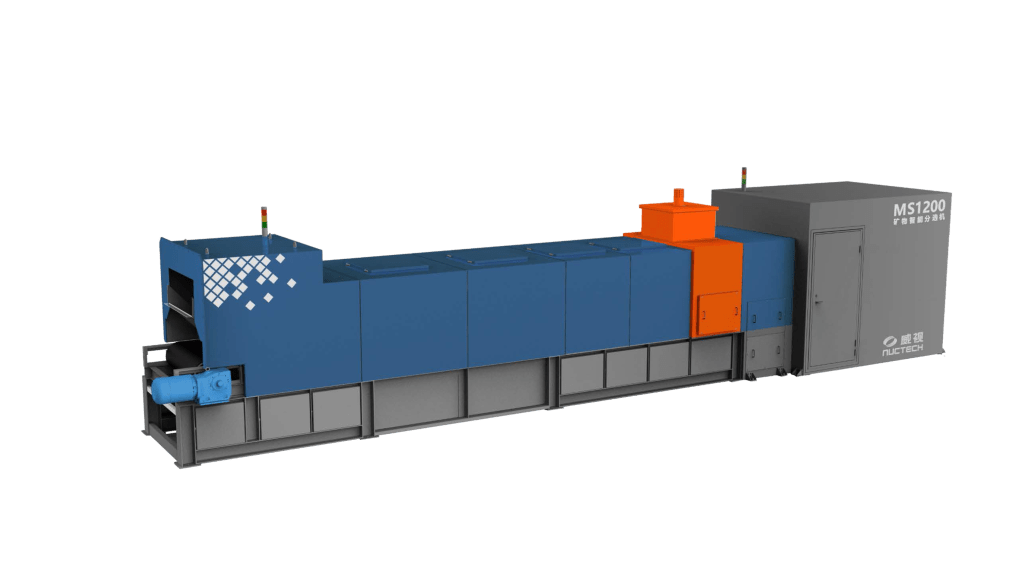

Intelligent Ore Sorting System

Core Technology

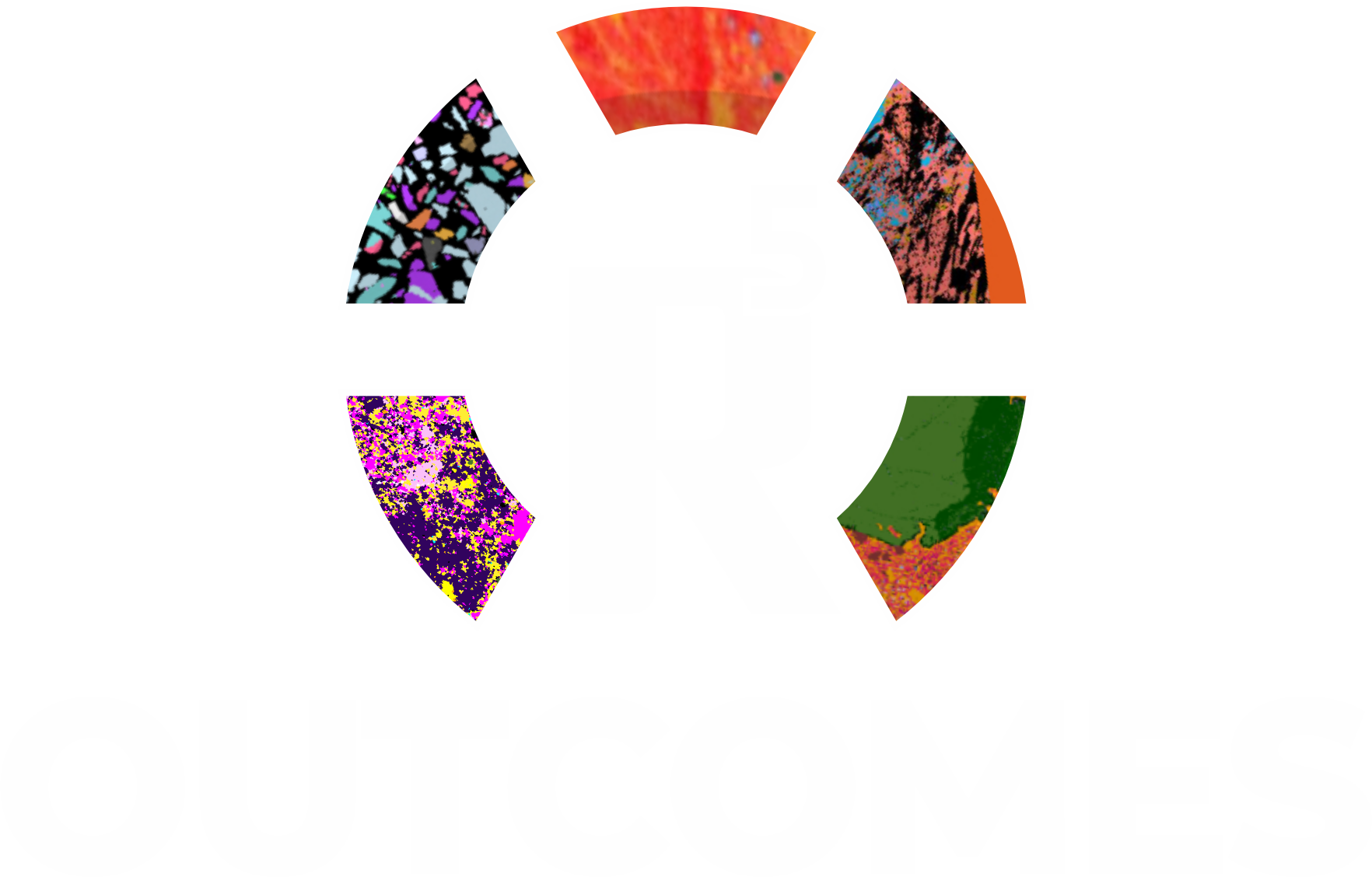

Nuctech’s Intelligent Ore Sorting System is based on X‑ray Transmission (XRT) imaging, supported by optional machine‑vision and multi‑sensor modules (XRF, neutron excitation, IR/microwave, electromagnetic analysis).

The system measures internal density/atomic‑number contrasts within individual ore particles and uses high‑pressure air jets for real‑time separation.

Key detection capabilities

- XRT: differentiates ore vs. waste by atomic number contrast

- XRF: elemental composition for precious/base metals

- Neutron excitation/transmission: lithium, gold, copper, antimony

- IR/microwave: thermal conductivity for Mn, Sn

- Visible light: surface texture for fluorite, Pb‑Zn

- EM analysis: conductivity/magnetism for Fe, Cu ores

This multi‑sensor flexibility allows deployment across coal, industrial minerals, and metal ores.

Product Category: Ore Sorting Units, Instruments, Coal, Metal Ore Mining, Cement & Non-metallic resources, Ash fusion Analyzer, CKIC.

Features

Process Integration

The system is designed for pre‑concentration and waste rejection prior to grinding and flotation.

Typical integration points

- ROM → coarse crushing → screening → XRT sorting → mill feed

- Reduces the volume of waste entering the comminution circuit

- Improves downstream flotation performance

- Lowers energy consumption (grinding energy reduction is significant)

Coal applications

- Replaces heavy‑media separation, jigging, and manual sorting

- Reduces slime generation and eliminates media consumption

- Produces higher‑CV lump coal suitable for direct sale

Performance Characteristics

Sorting accuracy

- High‑precision detectors + AI algorithms

- Fast image processing and high‑speed ejection valves

- Typical sorting accuracy: >90–95% depending on ore type

Throughput

- Models available from 30 t/h to 330 t/h per machine

- Particle size ranges:

- 300–50 mm

- 100–25 mm

- 50–10 mm

- Mobile units available for field trials and remote operations

Energy & water

- Dry process — no water, no chemicals

- Unit power consumption is ~20% of traditional beneficiation

- Reduces mill energy by removing barren rock early

Environmental & Operational Design

- Fully enclosed, dust‑proof, waterproof, and explosion‑proof

- Operates from –40°C to +50°C

- Radiation shielding exceeds national standards

- Multiple emergency stops, multi‑camera monitoring

- Remote, local, and handheld operation modes

Radiation Safety

- X-ray technology is adopted to ensure that no ray remains after power failure

- X-ray shielding materials such as lead and steel are used to ensure the safety of system boundary

- the radiation safety standard of the system exceeds national standards to fully ensure the safety of staff

Application

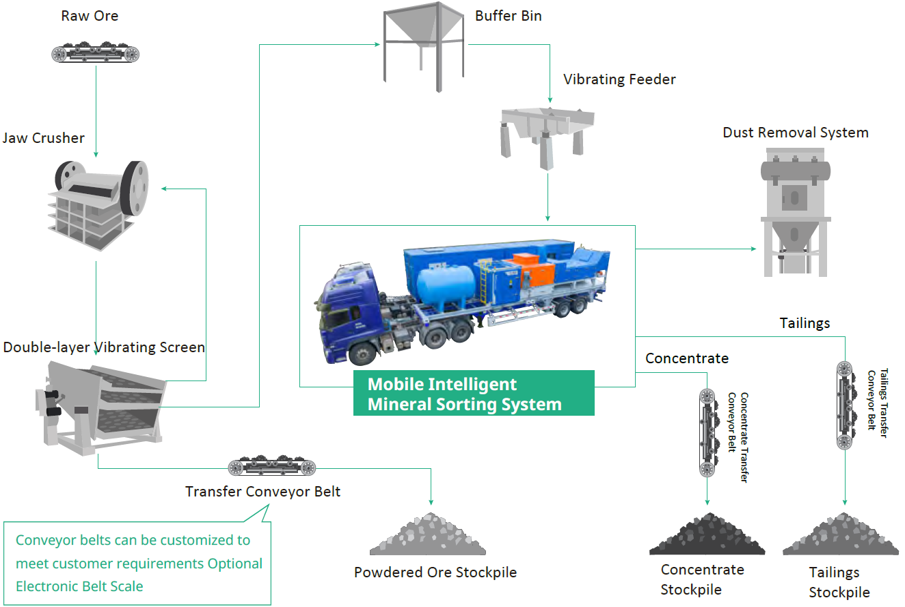

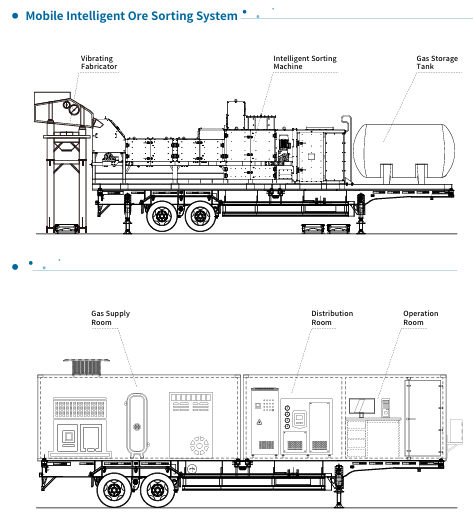

Nuctech offers two types of ore sorting systems: a static (fixed‑installation) system designed for permanent processing plants, and a mobile system engineered for rapid deployment, field trials, and remote mining operations.

Product Series

Nuctech offers several ore sorting product lines:

A. Raw Coal Sorting Series

- Particle sizes: 300–50 mm, 100–25 mm, 50–10 mm

- Capacity: 30–330 t/h depending on model

- Replaces heavy‑media separation, jigging, and manual sorting

- Improves calorific value and reduces gangue

B. Coal‑Bearing Kaolinite Sorting Series

- Recovers kaolin from coal gangue

- Replaces manual picking

- Sorting accuracy: >90%

- Capacity: 80–440 t/h

C. Metal Ore Sorting Series

- For copper, tin, silver, tungsten, molybdenum, etc.

- Particle sizes: 100–25 mm, 60–10 mm

- Used for pre‑concentration to reduce grinding energy

- Removes waste rock before milling

D. Industrial Minerals Series

- For phosphate, fluorite, etc.

- Improves grade before flotation

- Reduces processing cost

E. Mobile Intelligent Ore Sorting System

- Fully integrated mobile unit

- Fast deployment (≤3 days)

- Suitable for field trials and remote mines

- Includes sorter, control system, dust removal, and gas system

Application Case Highlights Examples

| Coal (China) Inner Mongolia: 150–25 mm coal, >100 t/h CV increased from 2500 → 4800 kcal Coal-in-gangue: <3% Shanxi: 300–50 mm coal, >200 t/h Gangue discharge: >97% | Metal Ores Tin (Bolivia): Enrichment ratio: 7× Recovery: 81.5% Silver (Mexico): Grade improved from 56.7 g/t → 108.5 g/t Recovery: 96% |

Industrial Minerals

- Phosphate (Hubei):

- Concentrate grade: 25.4% P₂O₅

- Recovery: 55%

- Tailings re‑sorting improves overall yield

- Kaolinite

- Sorting accuracy: >90–93%

- Replaces manual picking

- Annual capacities up to 1.3 Mt

For more information or inquiries, please contact us.

Datasheet

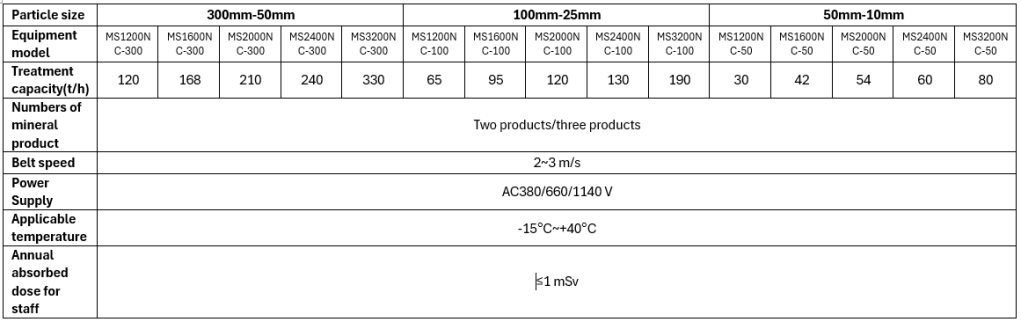

Raw Coal Sorting Series

Raw Coal Sorting Series Industrial Minerals Series

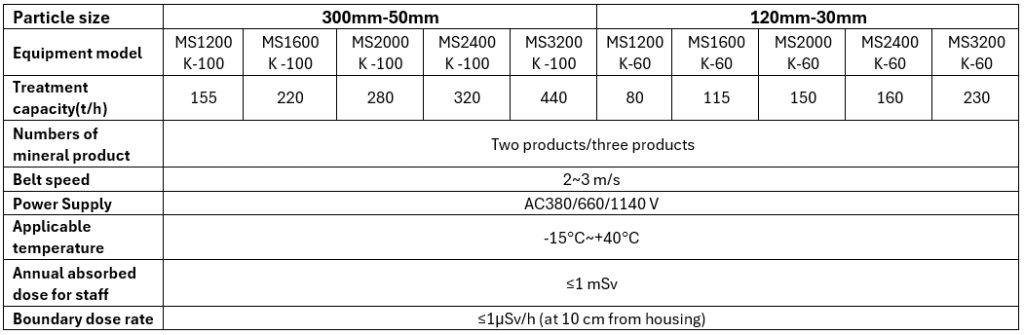

Coal Bearing Kaolinite Sorting Series

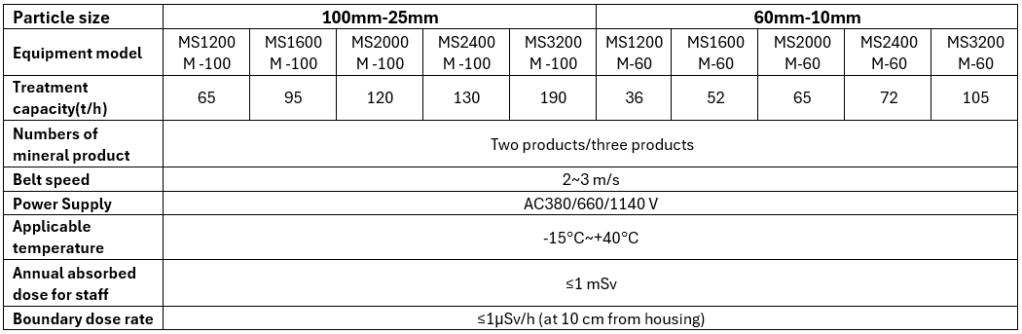

Metal Mineral Series

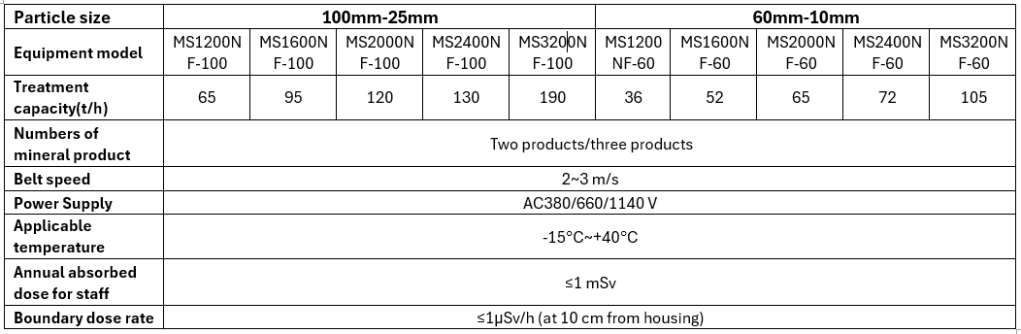

Industrial Minerals Series

The parameters in the table are typical parameters of the product and can be adjusted according to customer needs.

Mobile Intelligent Ore Sorting System

| Parameter | Specification |

| Belt width | 1600 mm |

| Boundary dose rate | ≤1 μSv/h (at 10 cm from housing) |

| Power requirements | 380±10% VAC, three‑phase five‑wire, 160 kW |

| Dimensions | 8700 × 2550 × 2500 mm |

| Transport vehicles | 12250 × 2480 × 1425 mm, 40‑ft two‑axle trucks |

| Gross weight | ≤15 t (sorter body, excluding frame, vibrating feed screen) |

| Applicable temperature | −20 °C to +40 °C (customizable) |

| Transit time (short-range transit versus deployment) | ≤3 days (with chassis car) |