Online LIBS Elemental Analysis

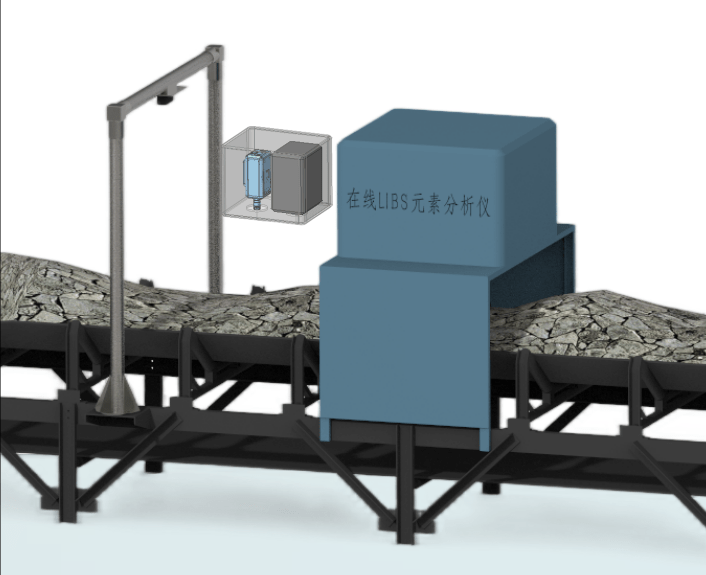

The online LIBS elemental analyser, developed by our partner Nuctech, is based on laser-induced breakdown spectroscopy (LIBS) technology, is specifically designed for mine conveyor belts and metal separation scenarios,

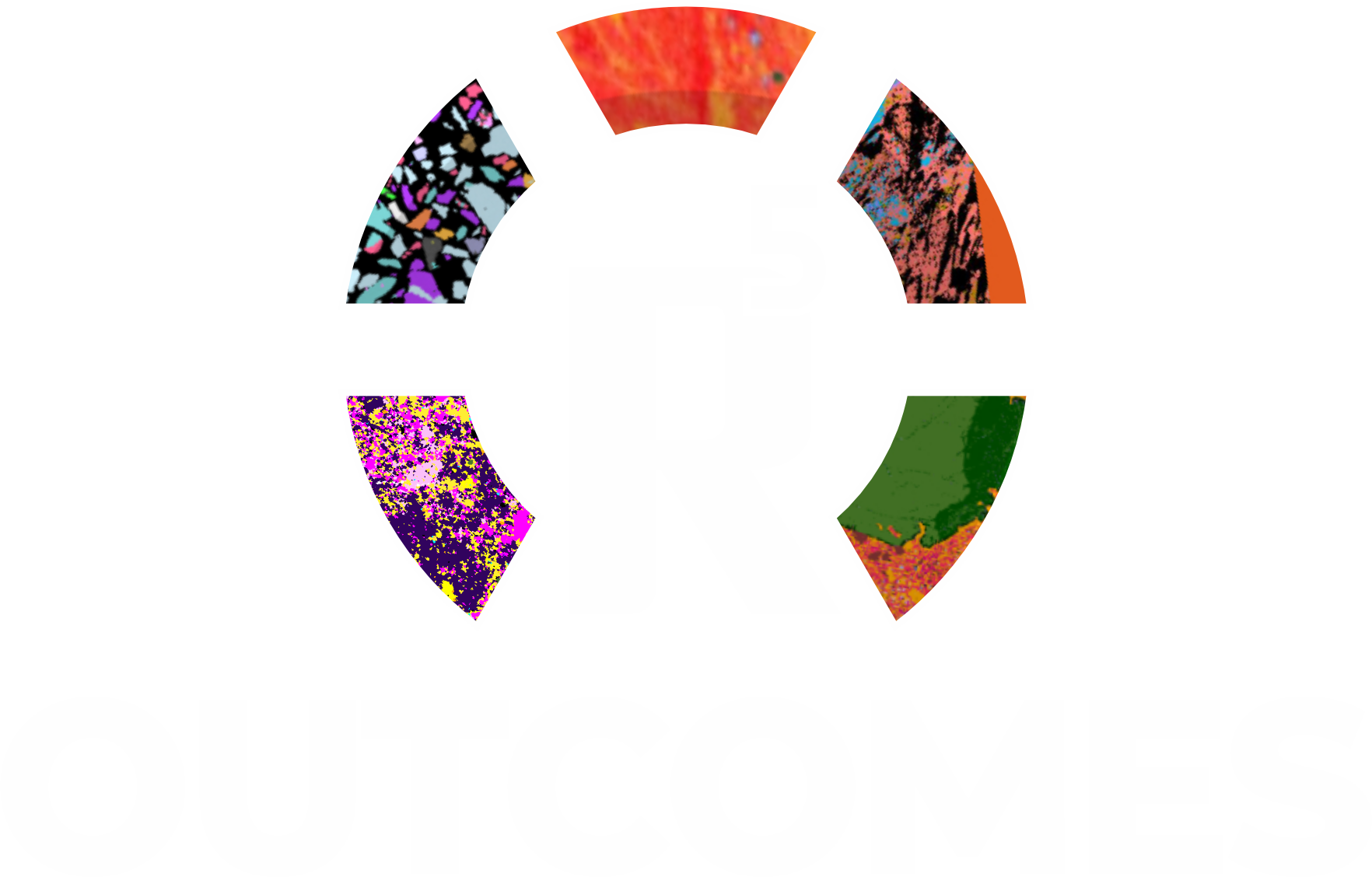

enabling real-time online detection and analysis of ore and metal components. This device is directly integrated above the conveyor belt. It uses high-energy laser pulses to excite the plasma on the surface of ores and metals and combines AI algorithms to analyse spectral data. It can complete qualitative and quantitative analysis of over 50 elements such as Fe, Cu, Li, and Mg within 1 second, with detection accuracy reaching the ppm level and repeatability error less than 5%.

The system adopts a modular design and supports seamless integration with various central control management platforms. It can obtain ore and metal detection data once every second

and is compatible with high-speed conveyor belts (≤4m/s), providing a contactless and full process detection solution for the detection process.

Product Category: Rapid Analysis for QA/QC, Elemental Analyzer, Cement & non-metallic resources, Coal, Metal Ore Mining, Nuctech.

Application

- Real‑time quality analysis for conveyor‑belt ore/coal/cement grade monitoring

- Metal sorting and separation

- High‑speed production line elemental detection (≤4 m/s belt speed)

Features

- Fully automatic high throughput. It operates continuously for 24 hours, obtaining detection data once every second without any manual intervention.

- Precise and efficient analysis. Synchronous detection of over 50 elements, with detection limits as low as the ppm level and repeatability errors less than 5%. The built-in spectral drift compensation algorithm reduces the accuracy fluctuation by 40%.

- Industrial-grade hardcore performance. IP67 protection + wide temperature range (-20℃ to 50℃), dust-resistant and vibration resistant. The laser window is self-cleaning to ensure long-term detection stability.

- Intelligent interconnection control. Compatible with the integration of various intelligent supervision platforms.

Technical Data Sheet

Technology & Performance

| Parameter | Specification |

|---|---|

| Technology | LIBS spectral model |

| Elements detected | 50+ elements (e.g., Fe, Cu, Li, Mg) |

| Detection speed | ≤1 second per analysis |

| Detection accuracy | ppm‑level |

| Repeatability | <5% error |

| Spectral drift compensation | Reduces accuracy fluctuation by 40% |

| Spectral range | 180–960 nm (configurable per user requirements) |

| Detection distance | 1–3 m (depending on site conditions) |

| Test frequency | Adjustable; fastest ~1 second per test |

System & Operation

| Parameter | Specification |

|---|---|

| Operating system | Android / Windows |

| Communication | Gigabit Ethernet (RJ45), 5G |

| Installation | Mounted directly above conveyor belt |

| Operation mode | Fully automatic, 24/7 continuous detection |

| Throughput | Real‑time detection once per second |

| Integration | Supports seamless connection to central control and intelligent supervision platforms |

Environmental & Mechanical

| Parameter | Specification |

|---|---|

| Protection rating | IP67 (dust‑resistant, vibration‑resistant) |

| Operating temperature | –20°C to 50°C |

| Humidity | 10%–95% RH, non‑condensing |

| Laser window | Self‑cleaning design for long‑term stability |

Laser Specification

| Parameter | Specification |

|---|---|

| Laser wavelength | 1064 ± 1 nm |

| Maximum single pulse energy | ≤100 mJ |

| Pulse width | <10 ns |

| Repetition frequency | 20 Hz |