August – Technical Visit to CKIC Factory

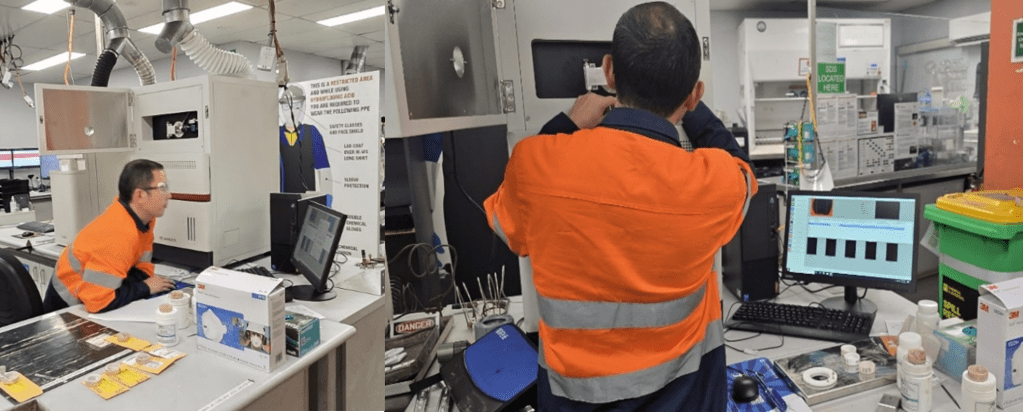

R5 Outcomes Director Maurice Wicks and Technical Engineer Uurtsaikh Dagvatseren visited CKIC’s factory to receive detailed training on the XRF fusion machine and the Microwave Acid Digestion System, as well as to conduct test work using various Australian ore and coal samples.

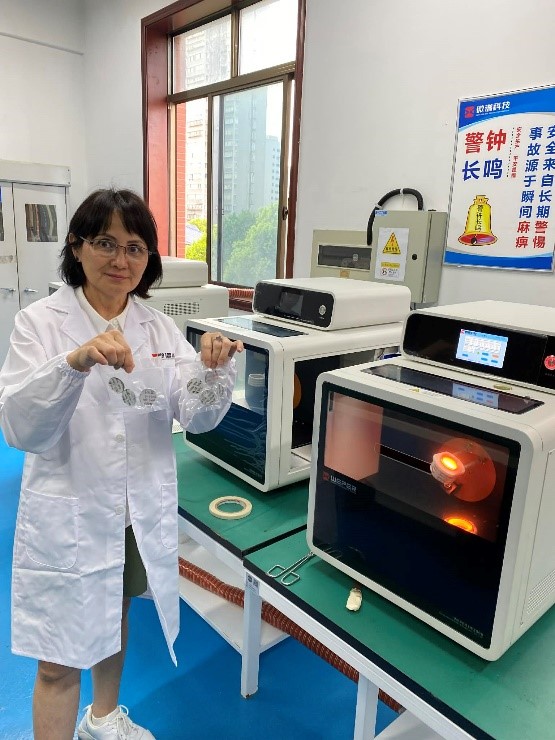

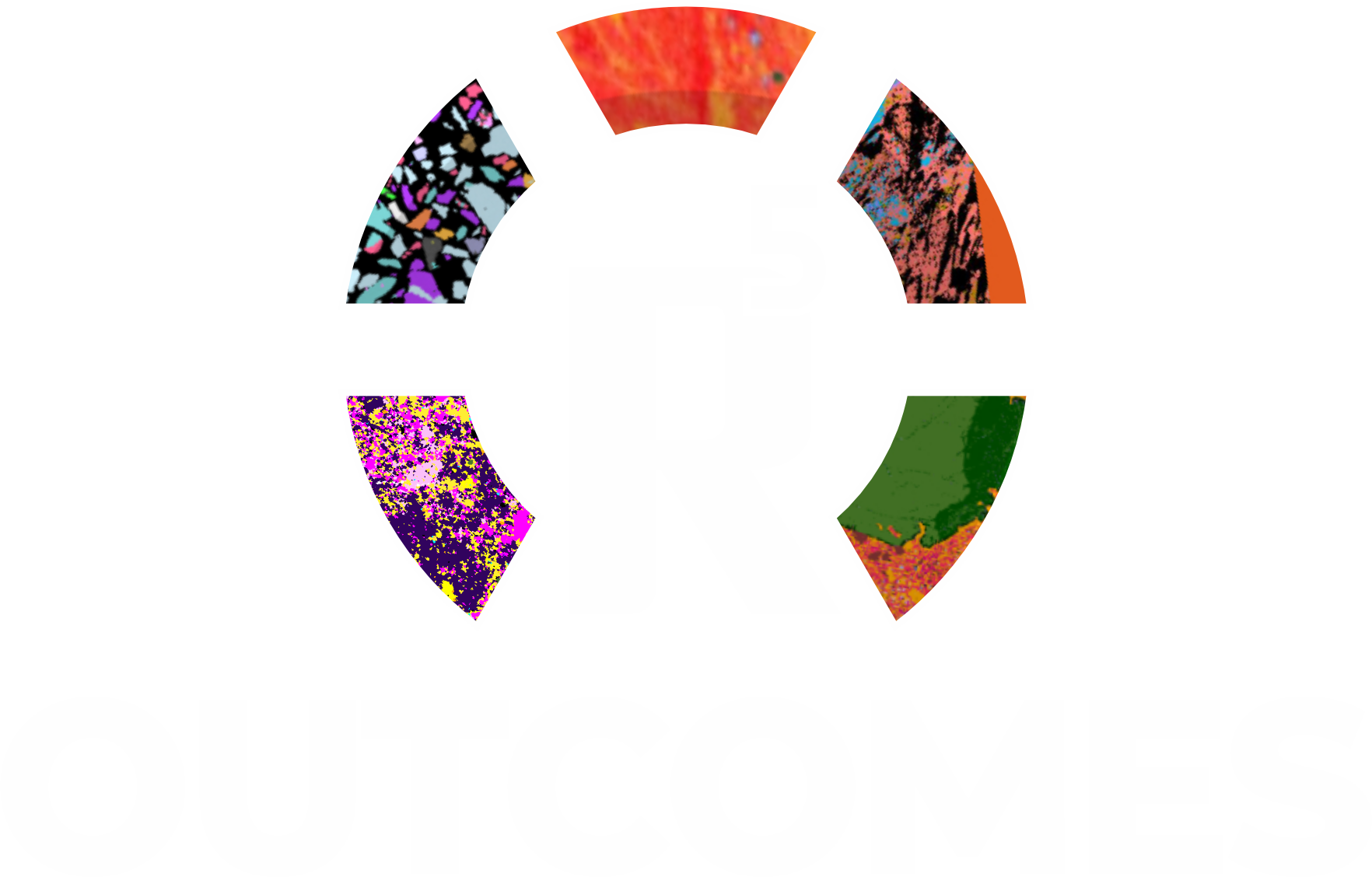

At the end of the visit, Uurtsaikh collaborated with CKIC’s research team to perform XRF fusion tests on a wide range of samples brought from Australia. These included 16 samples of iron ore, lithium, zircon, copper, nickel, lead, and silver ores with different concentrations; 4 vanadium ore samples; 10 matrix types from the Newmont gold deposit; and 8 coal ash samples. A total of 38 fusion beads were produced, all of which met the required quality standards.

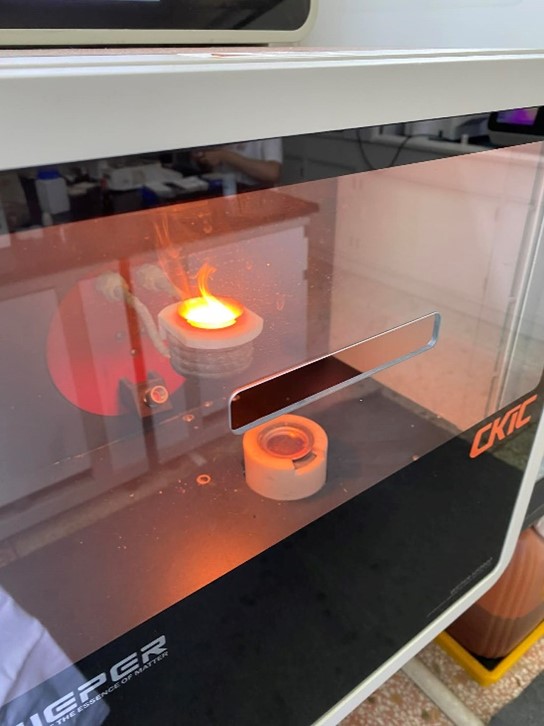

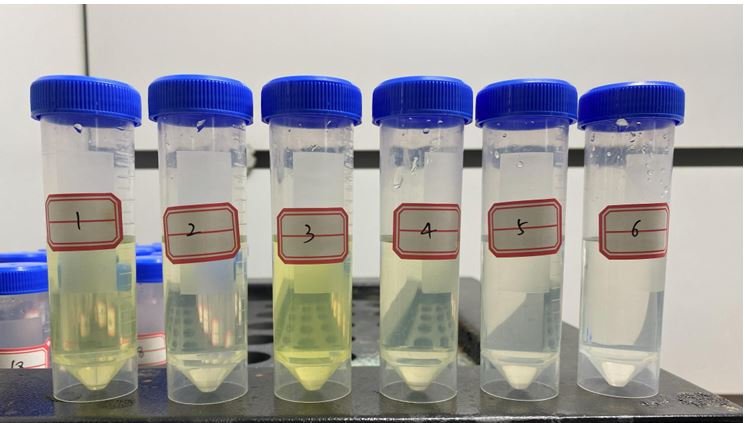

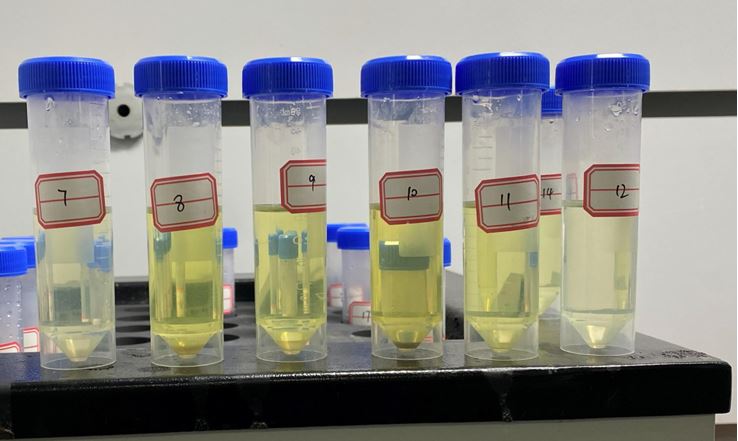

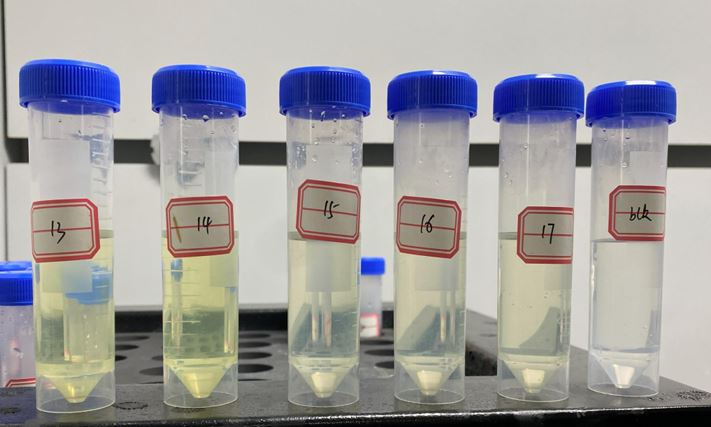

The fusion machine, which uses induction heating, operated at a similar speed to the gas‑heated fusion machines commonly used in Australia. However, it demonstrated clear advantages in software capability and safety performance. Additional test work was carried out using CKIC’s Super Microwave Acid Digestion System, performing both 3‑acid and 4‑acid digestions on 10 matrix samples from the Newmont gold deposit and 25 coal samples. The results showed that the system is highly suitable for low‑complexity samples, particularly for trace‑element determination in coal and for copper and nickel concentration digestion. However, it was concluded that the system is not ideal for complex samples with highly variable compositions.