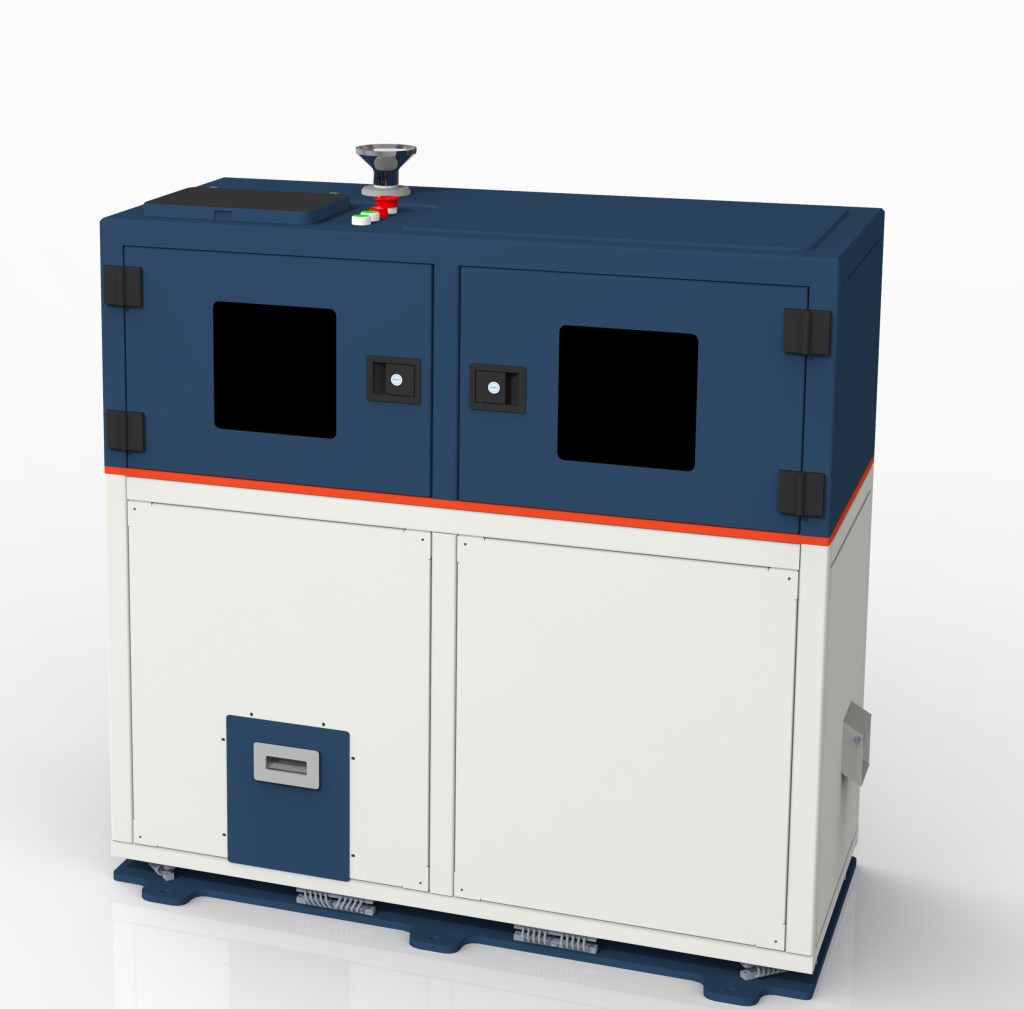

ALS1000 Fully Automated LIBS Elemental Analyzer for Laboratory and On-Line Ore Control

The ALS1000, developed by our partner Nuctech, is a fully automatic LIBS elemental analyzer designed for dynamic sampling and closed‑loop ore‑sorting applications. It diverts samples directly from the main conveyor to a bypass detection area, where high‑energy lasers and AI algorithms deliver second‑level analysis of 50+ elements (Li–U) with ppm‑level accuracy and <5% repeatability error.

The system integrates with six‑axis robotic arms and automated sample‑taking equipment to enable fully unmanned operation. Standardised sample preparation eliminates human variability, moisture effects, and non‑standard handling. The ALS1000 is fully automated, free from X‑ray ionising radiation, and requires no environmental impact assessment—ensuring safe, reliable, and high‑performanceelemental analysis both in the field and in the laboratory.

Product Category: Rapid Analysis for QA/QC, Elemental Analyzer, Cement & Non-metallic resources, Coal, Metal Ore Mining, Nuctech.

Features

Key Features

High‑Precision Dynamic Sampling

- Intelligent weighted‑random sampling algorithm automatically adjusts sampling frequency based on ore flow rate and particle size distribution.

- Ensures highly representative data with deviation <5%.

Fast, Automated Elemental Analysis

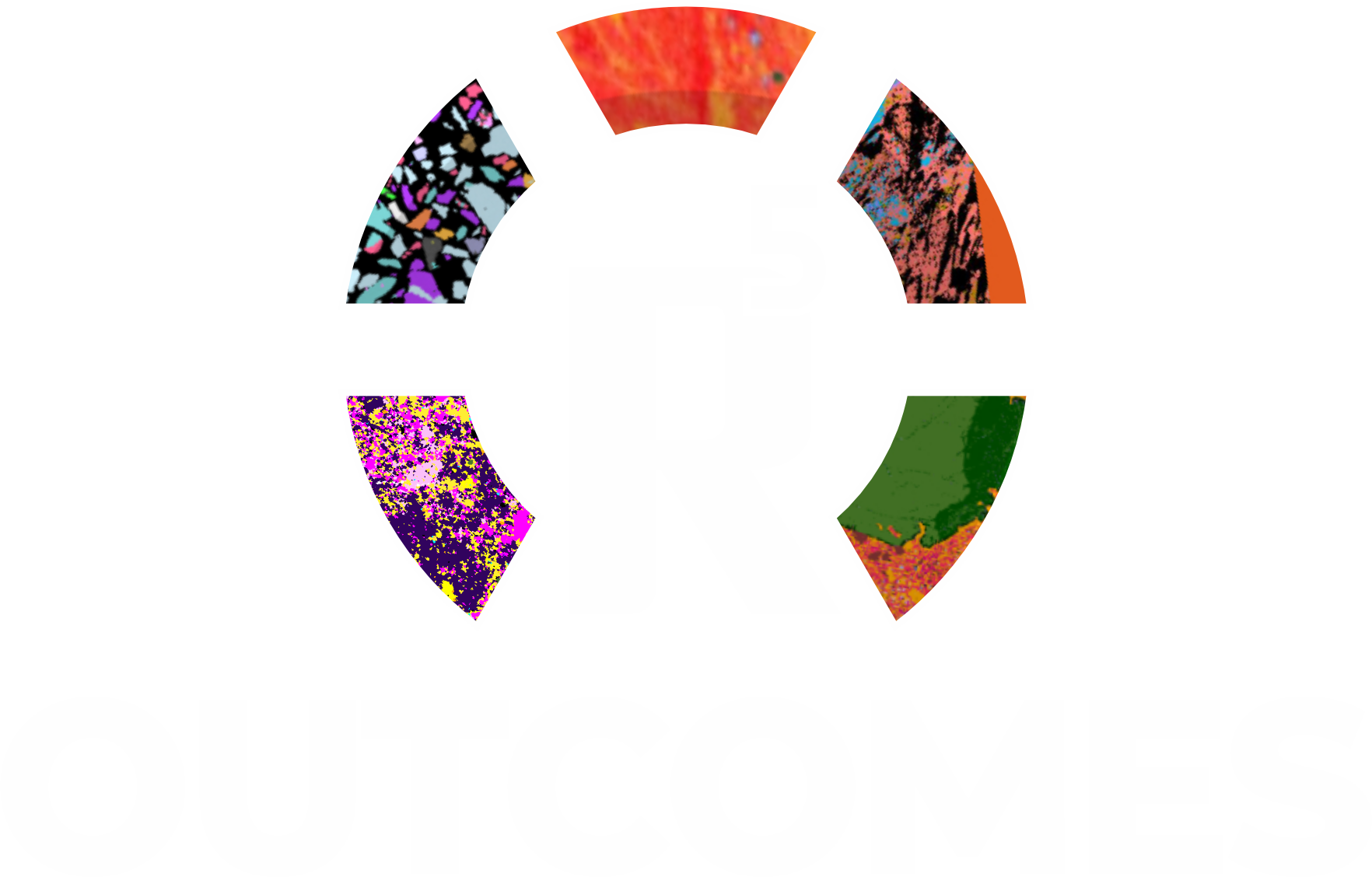

- LIBS technology combined with AI algorithms delivers second‑level analysis of 50+ elements (Li–U).

- Single detection time ≤1 second with ppm‑level accuracy and repeatability error <5%.

Fully Automatic, Low‑Intervention Operation

- Integrated sample injection and preparation modules support unmanned operation.

- Compatible with six‑axis robotic arms and automated sample‑taking systems.

- Each sampling and testing cycle completes in approximately 15 minutes.

Robust Design for Harsh Environments

- IP68 protection rating with self‑cleaning laser window and dust‑isolation chamber.

- Reliable performance in high‑dust, high‑humidity mining environments.

Safe, Non‑Radiative Technology

- No X‑ray ionising radiation.

- No environmental impact assessment required.

- Safe for operators and compliant with strict site requirements.

Flexible Integration & Control

- Supports Modbus TCP and OPC UA protocols.

- Seamlessly connects to central control and plant management systems.

Versatile Deployment

- Suitable for on‑conveyor ore control, dynamic sampling, closed‑loop sorting, and laboratory elemental analysis.

Application

- Rapid analysis of ore qualities for grade, impurities monitoring and variability directly at the production line or in the laboratory.

- Train or truck ore quality verification

Rapid elemental analysis for inbound/outbound ore shipments. - Laboratory elemental analysis

High‑precision LIBS testing for research, QA/QC, and metallurgical studies. - Closed‑loop sorting and process optimisation

Feed real‑time elemental data into automated sorting or plant control systems - Raw material quality monitoring for wide range of minerals

Data sheet

- Technology & Performance

| Parameter | Specification |

| Technology | LIBS + near‑infrared dual‑spectrum model |

| Elements detected | 50+ (Li–U) |

| Detection speed | ≤1 second per measurement |

| Accuracy | ppm‑level |

| Repeatability | <5% error |

| Sampling cycle | ~15 minutes (automatic) |

- System & Operation

| Parameter | Specification |

| Operation interface | Industrial 10‑inch touchscreen |

| Operating system | Android / Windows |

| Communication | Gigabit Ethernet (RJ45), 5G |

| Injection volume | ~10 g |

| Sample handling | Compatible with six‑axis robotic arms and automated prep systems |

- Environmental Conditions

| Parameter | Specification |

| Temperature | –20°C to 50°C |

| Humidity | 10%–95% RH, non‑condensing |

| Protection rating | IP68 (dust & water resistant) |

- Power & Safety

| Parameter | Specification |

| Power supply | 220 VAC ±10%, 50 Hz |

| Peak power | 2 kW |

| Average power | 1 kW |

| Safety | No X‑ray radiation; no EIA required |

- Anti‑Tampering & Monitoring

| Parameter | Specification |

| Anti‑cheating | Injection system linkage, door‑open alarm |

| Monitoring | On‑site video operation status monitoring |

- Sample Requirements

| Parameter | Specification |

| Max sample volume | ≤50 cm³ |

| Max particle size | ≤5 mm (≤50 mm with sample prep equipment) |

| Surface moisture | No visible moisture (≤15% with sample prep equipment) |